Have you ever wondered what makes our modern rechargeable batteries so efficient and reliable? The answer lies partly in a material called "battery graphite." This remarkable substance is an integral component in the production of lithium-ion batteries, which are ubiquitous in devices like smartphones, laptops, and electric vehicles. Understanding the significance of battery graphite not only sheds light on the technological advancements of recent years but also provides insight into the future of energy storage solutions.

As technology continues to evolve at an unprecedented pace, the demand for efficient and sustainable energy storage systems grows exponentially. Battery graphite plays a crucial role in meeting this demand due to its unique properties, such as high electrical conductivity and stability. These characteristics make it an ideal material for use in the anodes of lithium-ion batteries, which are essential for powering a wide range of consumer electronics and electric vehicles. This article will delve into the fascinating world of battery graphite, exploring its properties, applications, and the role it plays in shaping the future of energy storage.

In addition to its technical applications, battery graphite is also a topic of interest for policymakers, environmentalists, and investors. The extraction and production of graphite have significant environmental and economic implications, making it a subject of considerable debate and research. By examining the full spectrum of issues related to battery graphite, from its extraction and processing to its environmental impact and market trends, this article aims to provide a comprehensive overview of this vital material and its place in the modern technological landscape.

Table of Contents

- Introduction to Battery Graphite

- The Properties of Battery Graphite

- Manufacturing Process

- Applications in Lithium-Ion Batteries

- Environmental Impact

- Economic Implications

- Future Trends

- Challenges and Solutions

- Battery Graphite vs Other Materials

- Innovations in Battery Graphite

- Recycling and Sustainability

- Global Market Analysis

- Regulations and Policies

- Impact on Electric Vehicles

- Conclusion

- FAQs

Introduction to Battery Graphite

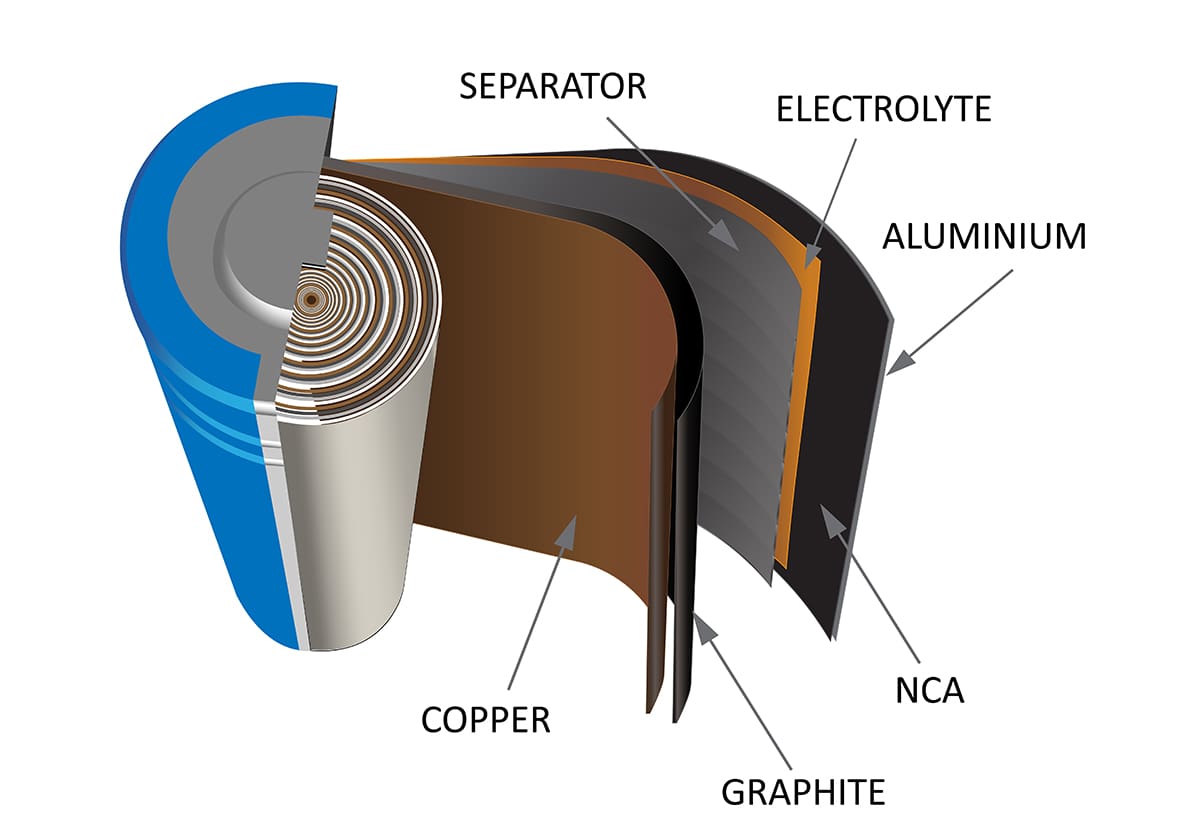

Battery graphite is a form of carbon that is highly conductive and structurally stable. It is used primarily in the anodes of lithium-ion batteries, where it acts as the host structure for lithium ions during the charge and discharge cycles. The high conductivity of graphite allows for efficient electron flow, which is crucial for the performance of rechargeable batteries.

Graphite used in batteries can be either natural or synthetic. Natural graphite is mined and then purified, while synthetic graphite is produced from carbon-rich materials through a high-temperature process. Both types of graphite have their own advantages and disadvantages, which will be discussed in detail later in this article.

The use of graphite in batteries is not a new concept. However, its importance has increased significantly with the rise of portable electronics and electric vehicles. As these technologies continue to evolve, the demand for high-performance batteries—and by extension, high-quality battery graphite—continues to grow. Understanding the role of graphite in these applications is essential for anyone interested in the future of energy storage technologies.

The Properties of Battery Graphite

Battery graphite possesses several key properties that make it ideal for use in lithium-ion batteries. These include high electrical conductivity, chemical stability, and a layered structure that allows for the intercalation of lithium ions.

Electrical conductivity is one of the most important properties of battery graphite. This characteristic enables efficient electron flow, which is crucial for the performance of rechargeable batteries. Graphite's high conductivity is due to its unique structure, which consists of layers of carbon atoms arranged in a hexagonal lattice. These layers can slide over each other, allowing electrons to move freely.

Chemical stability is another important property of battery graphite. The material is resistant to chemical reactions with the electrolyte, which helps to extend the lifespan of the battery. Additionally, graphite is capable of withstanding high temperatures without degrading, making it suitable for use in a wide range of applications.

The layered structure of graphite is particularly important for its role in lithium-ion batteries. During the charging process, lithium ions are intercalated—or inserted—between the layers of graphite. This process is reversible, allowing the ions to move back out during discharge. This ability to accommodate and release lithium ions is what makes graphite such an effective anode material.

Manufacturing Process

The manufacturing process for battery graphite varies depending on whether natural or synthetic graphite is being produced. Natural graphite is extracted from mines and then purified to remove impurities that could affect battery performance. This purification process typically involves crushing the graphite ore, followed by flotation to separate the graphite from other minerals.

Synthetic graphite, on the other hand, is produced through a different process. It begins with a carbon-rich feedstock, such as petroleum coke or coal tar pitch. This material is subjected to high temperatures in a process known as graphitization, which rearranges the carbon atoms into the desired hexagonal lattice structure.

Both natural and synthetic graphite must undergo further processing to be used in batteries. This includes shaping the material into the appropriate form for anodes and coating it with a protective layer to improve performance and longevity. The final product is then tested to ensure it meets the necessary specifications for use in lithium-ion batteries.

Applications in Lithium-Ion Batteries

The primary application of battery graphite is in the anodes of lithium-ion batteries. In this role, graphite serves as the host structure for lithium ions during the charging and discharging cycles. When a battery is charged, lithium ions move from the cathode to the anode, where they are intercalated between the layers of graphite. During discharge, the ions move back to the cathode, releasing energy in the process.

This intercalation-deintercalation process is essential for the operation of lithium-ion batteries. Graphite's unique structure and properties make it particularly well-suited for this role, allowing for efficient energy storage and release. As a result, battery graphite is used in a wide range of applications, from consumer electronics to electric vehicles.

In addition to its role in lithium-ion batteries, graphite is also being explored for use in other types of energy storage systems. These include solid-state batteries, which offer the potential for higher energy densities and improved safety compared to traditional lithium-ion batteries. As research in this area continues, the demand for high-quality battery graphite is likely to increase.

Environmental Impact

The production of battery graphite has significant environmental implications. The mining and processing of natural graphite can lead to habitat destruction, water pollution, and air pollution. Additionally, the production of synthetic graphite requires large amounts of energy, contributing to greenhouse gas emissions.

Efforts are being made to address these environmental concerns. For example, researchers are exploring more sustainable methods of extracting and processing graphite, such as using renewable energy sources and developing more efficient purification techniques. Additionally, recycling programs are being developed to recover graphite from used batteries, reducing the need for new production.

Despite these efforts, the environmental impact of battery graphite production remains a significant challenge. Continued research and innovation are needed to develop more sustainable practices and mitigate the negative effects of graphite production on the environment.

Economic Implications

The demand for battery graphite is closely tied to the growth of the lithium-ion battery market. As the demand for electric vehicles and portable electronics increases, so too does the need for high-quality battery graphite. This has significant economic implications, both for the graphite industry and for the broader economy.

The graphite market is highly competitive, with numerous companies vying for a share of the growing demand. This has led to increased investment in graphite mining and processing facilities, as well as research and development efforts aimed at improving the performance and sustainability of battery graphite.

At the same time, the price of graphite can be volatile, influenced by factors such as supply chain disruptions, geopolitical tensions, and changes in demand. This volatility can pose challenges for companies operating in the graphite market, requiring them to carefully manage their production and pricing strategies.

Future Trends

The future of battery graphite is closely tied to the evolution of energy storage technologies. As demand for more efficient and sustainable batteries continues to grow, so too does the need for high-performance materials like graphite. Several trends are likely to shape the future of the battery graphite market, including advancements in battery technology, increasing emphasis on sustainability, and shifts in global supply and demand dynamics.

One of the key trends is the development of next-generation batteries that offer higher energy densities and improved safety. These include solid-state batteries, which use a solid electrolyte instead of the liquid electrolyte found in traditional lithium-ion batteries. Graphite is being explored as a potential anode material for these new battery types, given its excellent conductivity and stability.

Another important trend is the increasing focus on sustainability in the graphite supply chain. Companies are investing in more environmentally friendly extraction and processing methods, as well as recycling initiatives to recover graphite from used batteries. This is driven by both regulatory pressures and growing consumer demand for sustainable products.

Finally, shifts in global supply and demand dynamics are likely to impact the battery graphite market. As countries seek to secure their own supplies of critical materials, new sources of graphite are being developed, and existing production facilities are being expanded. This could lead to changes in the global competitive landscape and influence the availability and pricing of battery graphite.

Challenges and Solutions

The battery graphite industry faces several challenges, including environmental concerns, supply chain disruptions, and technological advancements. Addressing these challenges requires a combination of innovation, collaboration, and strategic planning.

One of the main challenges is the environmental impact of graphite production. Companies are investing in more sustainable extraction and processing methods, such as using renewable energy sources and developing more efficient purification techniques. Additionally, recycling programs are being developed to recover graphite from used batteries, reducing the need for new production.

Supply chain disruptions can also pose challenges for the battery graphite industry. These disruptions can be caused by factors such as geopolitical tensions, natural disasters, and changes in demand. To mitigate these risks, companies are diversifying their supply chains, investing in new production facilities, and developing strategic partnerships with suppliers.

Technological advancements also present challenges, as companies must adapt to new battery technologies and changing market demands. This requires ongoing research and development efforts to improve the performance and sustainability of battery graphite. Collaboration with research institutions, government agencies, and other stakeholders is essential to drive innovation and address these challenges.

Battery Graphite vs Other Materials

While graphite is a widely used anode material for lithium-ion batteries, other materials are also being explored for this purpose. These include silicon, lithium metal, and various types of carbon-based materials. Each of these materials has its own advantages and disadvantages, and the choice of material depends on factors such as performance, cost, and environmental impact.

Silicon, for example, has a much higher theoretical capacity than graphite, making it an attractive option for high-energy-density batteries. However, silicon also undergoes significant volume changes during charge and discharge cycles, which can lead to mechanical degradation and reduced battery lifespan. Researchers are working to address these challenges through the development of silicon-graphite composites and other innovative solutions.

Lithium metal is another alternative to graphite, offering even higher energy densities. However, lithium metal anodes are prone to the formation of dendrites, which can cause short circuits and reduce battery safety. Advances in electrolyte design and other technologies are being explored to overcome these challenges and enable the use of lithium metal in batteries.

Despite these alternatives, graphite remains the most widely used anode material for lithium-ion batteries, thanks to its excellent conductivity, stability, and cost-effectiveness. As research continues, it is likely that a combination of materials will be used to optimize battery performance and meet the diverse needs of different applications.

Innovations in Battery Graphite

Ongoing research and development efforts are driving innovations in battery graphite, aimed at improving its performance, sustainability, and cost-effectiveness. These innovations include the development of new graphite materials, advanced processing techniques, and novel applications for graphite in energy storage systems.

One area of innovation is the development of high-performance graphite materials with enhanced properties. This includes the creation of graphene, a single layer of carbon atoms arranged in a hexagonal lattice, which offers exceptional conductivity and mechanical strength. Graphene is being explored as a potential anode material for next-generation batteries, as well as for other applications in electronics and energy storage.

Advanced processing techniques are also being developed to improve the quality and performance of battery graphite. These techniques include the use of advanced purification methods, surface modifications, and coating technologies to enhance the conductivity, stability, and lifespan of graphite anodes.

Novel applications for graphite are also being explored, including its use in solid-state batteries, supercapacitors, and other emerging energy storage technologies. These applications offer the potential for higher energy densities, improved safety, and greater efficiency compared to traditional lithium-ion batteries.

Recycling and Sustainability

Recycling and sustainability are becoming increasingly important considerations for the battery graphite industry. As the demand for graphite continues to grow, so too does the need for sustainable practices that minimize the environmental impact of its production and use.

Recycling programs are being developed to recover graphite from used batteries, reducing the need for new production and minimizing waste. These programs involve the collection and processing of spent batteries to extract valuable materials, including graphite, for reuse in new batteries.

Sustainability efforts also focus on improving the environmental performance of graphite production. This includes the use of renewable energy sources, more efficient purification techniques, and the development of environmentally friendly extraction methods. These initiatives are driven by both regulatory pressures and consumer demand for sustainable products.

By adopting more sustainable practices, the battery graphite industry can reduce its environmental impact and contribute to the development of a circular economy, where materials are reused and recycled to minimize waste and conserve resources.

Global Market Analysis

The global market for battery graphite is experiencing significant growth, driven by the increasing demand for lithium-ion batteries in consumer electronics, electric vehicles, and renewable energy storage systems. This growth presents both opportunities and challenges for companies operating in the graphite industry.

Key market players are investing in new production facilities, research and development efforts, and strategic partnerships to capitalize on the growing demand for battery graphite. These investments are aimed at increasing production capacity, improving product quality, and enhancing the sustainability of graphite production.

At the same time, the market is facing challenges related to supply chain disruptions, price volatility, and regulatory pressures. Companies must navigate these challenges while maintaining competitiveness and meeting the evolving needs of their customers.

Overall, the global market for battery graphite is expected to continue growing in the coming years, driven by advancements in battery technology, increasing emphasis on sustainability, and the expanding adoption of electric vehicles and renewable energy systems.

Regulations and Policies

Regulations and policies play a crucial role in shaping the battery graphite industry, influencing everything from production practices to market dynamics. These regulations are designed to address environmental concerns, ensure the safety and reliability of batteries, and promote sustainable development.

Environmental regulations are a major focus for the battery graphite industry, as the extraction and processing of graphite can have significant environmental impacts. Governments around the world are implementing stricter environmental standards and requiring companies to adopt more sustainable practices. This includes the use of renewable energy sources, more efficient purification techniques, and the development of recycling programs.

Safety regulations are also important, as the performance and reliability of batteries are critical for consumer electronics, electric vehicles, and energy storage systems. These regulations require companies to meet specific standards for battery performance, durability, and safety, and to conduct rigorous testing and quality control measures.

Finally, policies promoting the adoption of electric vehicles and renewable energy systems are driving demand for lithium-ion batteries and, by extension, battery graphite. Governments are offering incentives for the use of electric vehicles, investing in charging infrastructure, and setting targets for renewable energy adoption. These policies are creating new opportunities for the battery graphite industry and driving innovation and investment in the sector.

Impact on Electric Vehicles

Battery graphite plays a critical role in the development and performance of electric vehicles (EVs). As the demand for EVs continues to grow, the need for efficient and reliable energy storage systems becomes increasingly important. Graphite's unique properties make it an ideal anode material for lithium-ion batteries, which are the most common type of battery used in EVs.

The use of battery graphite in EVs offers several advantages, including high energy density, long cycle life, and excellent conductivity. These characteristics are essential for meeting the performance requirements of modern electric vehicles, which demand high power output, fast charging times, and extended driving ranges.

In addition to its technical benefits, battery graphite also has economic advantages for the EV industry. Graphite is relatively abundant and cost-effective, making it a viable option for large-scale battery production. As the market for electric vehicles expands, the demand for battery graphite is expected to increase, driving further investment and innovation in the graphite industry.

Overall, battery graphite is a key enabler of the transition to electric vehicles, supporting the development of more sustainable and efficient transportation systems. As research and development efforts continue, new advancements in battery technology and graphite materials are likely to further enhance the performance and affordability of electric vehicles.

Conclusion

Battery graphite is a vital component in the development of modern energy storage systems, playing a crucial role in the performance and reliability of lithium-ion batteries. Its unique properties, such as high conductivity and chemical stability, make it an ideal material for use in a wide range of applications, from consumer electronics to electric vehicles.

As the demand for efficient and sustainable energy storage solutions continues to grow, so too does the importance of battery graphite. The industry is facing challenges related to environmental impact, supply chain disruptions, and technological advancements, but ongoing research and innovation are driving new solutions and opportunities.

Looking to the future, the battery graphite market is expected to continue expanding, driven by advancements in battery technology, increasing emphasis on sustainability, and the growing adoption of electric vehicles and renewable energy systems. By addressing these challenges and embracing new opportunities, the battery graphite industry can support the development of more sustainable and efficient energy storage solutions for the modern world.

FAQs

- What is battery graphite?

Battery graphite is a form of carbon used as an anode material in lithium-ion batteries. It is known for its high conductivity and stability, making it ideal for energy storage applications.

- How is battery graphite produced?

Battery graphite can be either natural or synthetic. Natural graphite is mined and purified, while synthetic graphite is produced from carbon-rich materials through a high-temperature process known as graphitization.

- What are the environmental impacts of battery graphite production?

The production of battery graphite can lead to habitat destruction, water pollution, and greenhouse gas emissions. Efforts are being made to develop more sustainable extraction and processing methods.

- What are the advantages of using battery graphite in electric vehicles?

Battery graphite offers high energy density, long cycle life, and excellent conductivity, making it ideal for electric vehicle batteries that require high power output and extended driving ranges.

- Are there alternatives to battery graphite for lithium-ion batteries?

Yes, alternatives such as silicon and lithium metal are being explored for use as anode materials. Each has its own advantages and challenges, but graphite remains the most widely used due to its balance of performance and cost-effectiveness.

- How is the battery graphite market expected to grow in the future?

The battery graphite market is expected to grow significantly, driven by advancements in battery technology, increasing emphasis on sustainability, and the expanding adoption of electric vehicles and renewable energy systems.

For further reading, explore resources like the International Energy Agency's reports on battery technologies and materials.

Article Recommendations

- Old Dollar Shave Club Handle

- Bec And Bridge Bridesmaid

- Gotlet

- Vintage Grandfather Wall Clock

- Freddie Prinze Jr Jessica Biel

- Melting Temperature Of Wax

- Cars With Great Audio Systems

- Drinking Ambien

- Thyronorm 50mcg

- Motion Ai Vs